Among the many subjects of interest in instrumentation (optical alignment, dimensional stability, outgassing, sealing technologies, adhesive behaviours, and many others) is heat transfer. Thermal management has significant impact on both product lifetime and field behaviour.

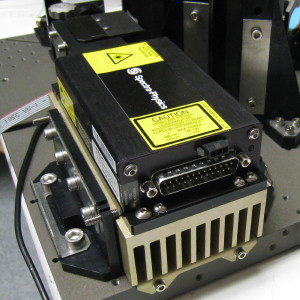

The laser's temperature is controlled by a thermo-electric. The waste heat (laser + TEC) is spread into the finned extrusion where forced-air convection produces a hot-side system R-value of 1.2 deg C/Watt. A very typical approach. Here, the heat exchanger's thermal behaviour is decoupled from the laser's pointing requirements.

Heat transfer problems arise all the time in high energy density photonic products. Aside from modelling and other traditional methods applied to analytical problem solving, the use of infrared technology brings several advantages. Among these: no thermal interference due to probes or probe wiring; immediate discovery of unforseen hot spots; extremely efficient set-up time; immediate user-awareness of thermal time constants; digital recording of the field for subsequent analysis. Temperatures in instrument design make imaging in the 8 to 14 micron region an invaluable tool.